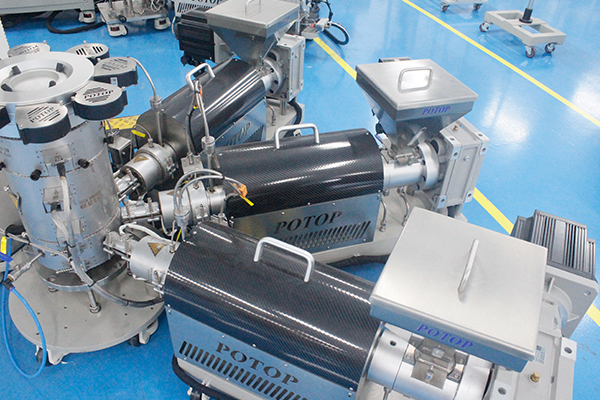

Applicable materials | PE, POF, PVC, LDPE, LLDPE, etc. |

Screw diameter | φ20mm |

Aspect ratio | 28 |

Screw speed | 0-120rpm |

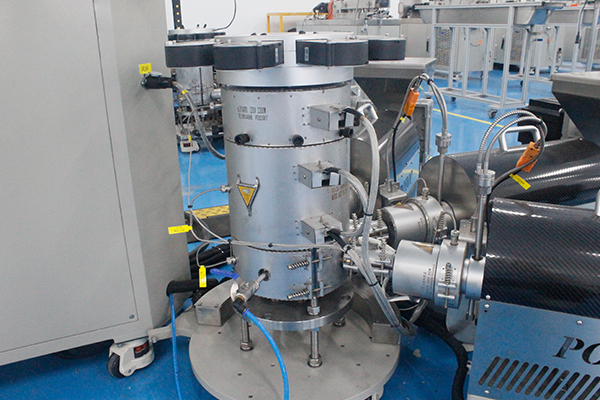

Die diameter | 45mm |

Number of co-extrusion layers | 3 |

Maximum folding diameter | 200mm |

Product specifications | 0.02-0.15mm |

Roller width | 220mm |

Line speed | 0-10m/min |

Pressure measurement range | 0-50MPa |

Pressure measurement accuracy | 0.5%FS |

Extrusion temperature control range | Room temperature -350℃ |

Temperature control accuracy | ±1℃ |

Working power | Three-phase five-wire 380VAC±10%, 50Hz |

Working air source | Compressed air, 6-8bar |

Cooling water | Soft water at room temperature, supply and return pressure difference: 2.5-4.0bar |

Working environment | Ambient temperature: 10-40℃; Relative humidity: ≤ 80%, no condensation |

Rated power | About 30kW |

Length × width × height | 2810mm×2130mm×2015mm |

Machine weight | About 1200kg |