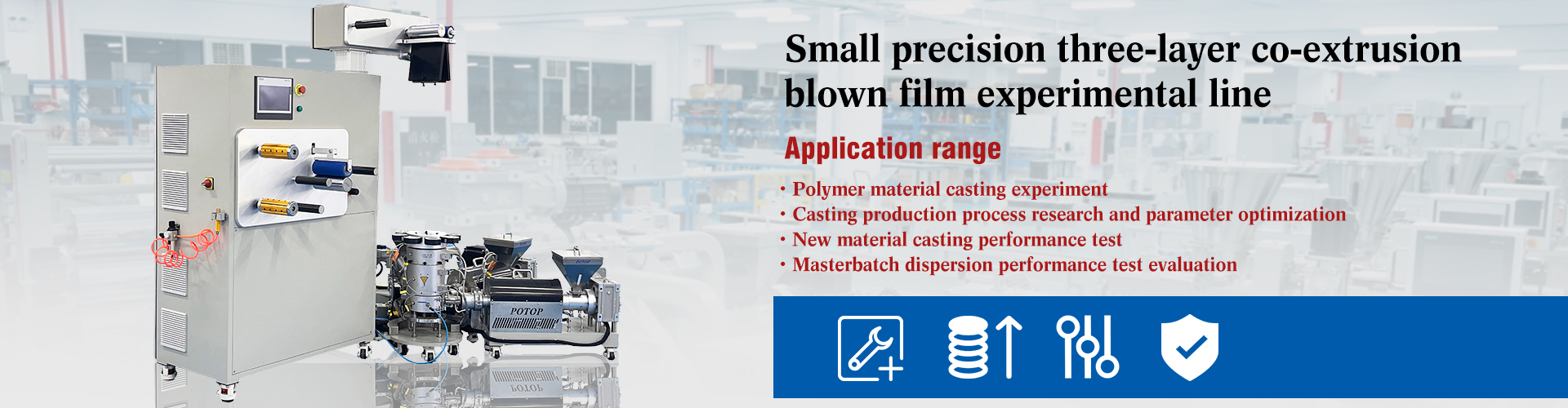

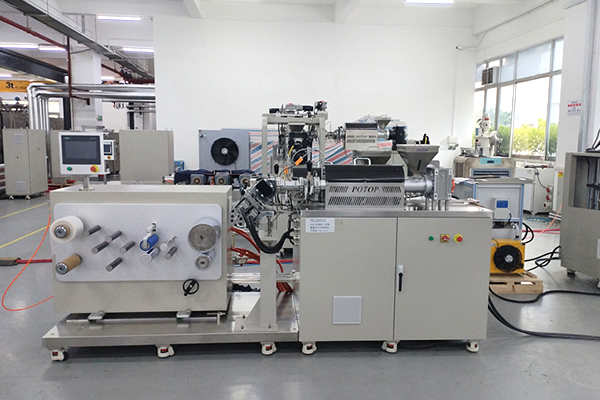

Small Precision ABA Co-Extrusion Casting Experimental Line

FPCL-20/30

The small precision ABA co-extrusion casting experimental line integrates 2 precision single-screw extruders, 1 set of three-layer co-extrusion casting die head, and 1 set of precision casting auxiliary machine into one experimental equipment, which can realize all functions of multi-layer extrusion, casting, pulling, trimming, winding, and trimming of a casting line. It is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for co-extrusion casting of polymer materials.