*The screw is driven by a servo motor, with stepless and precise speed regulation, stable plasticization and good consistency

*Digitally designed casting die head, smooth flow channel without dead corners and material stagnation, and uniform material discharge

*Each power roller is independently driven by a servo motor, with precise speed control and good synchronization performance

*The height of the casting roller can be raised and lowered to meet the process requirements of casting molding of materials with different melt strengths

*Hard chrome-plated mirror roller, high surface finish and no rust

*Based on PLC control system and touch screen operation interface, the equipment runs stably and the human-computer interaction is friendly

*Important experimental data is measured and displayed in real time with graphics and text, which is convenient for observation

*Humanized structural design, more convenient operation

*Optional online defect visual inspection system

*Optional constant tension and follow-up roller winding device to improve the film winding quality

*Optional air knife or electrostatic adsorber to improve the adsorption effect between the melt and the roller surface

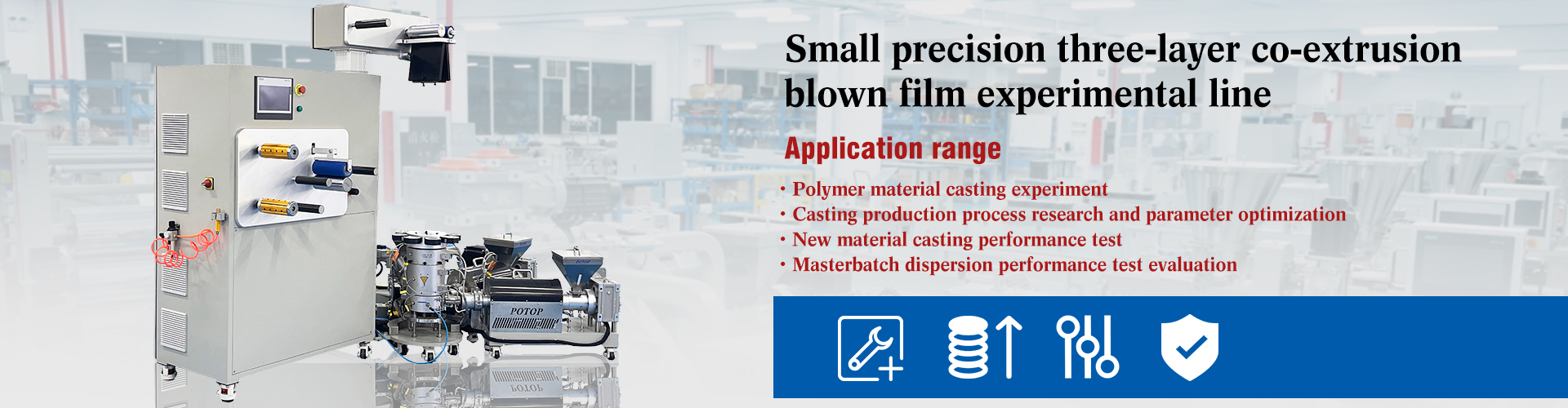

Application range

*Polymer material casting molding experiment

*Casting production process research and parameter optimization

*New material casting molding performance test

*Masterbatch dispersion performance test evaluation