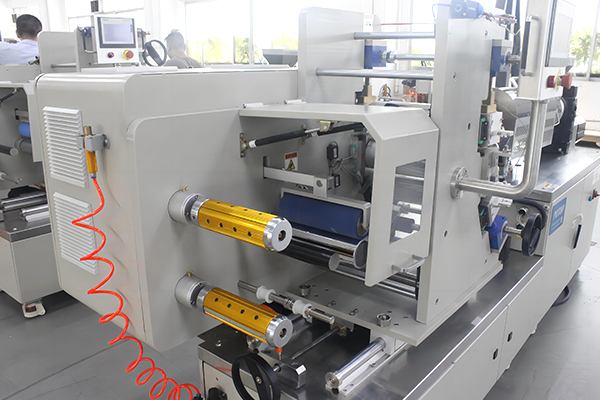

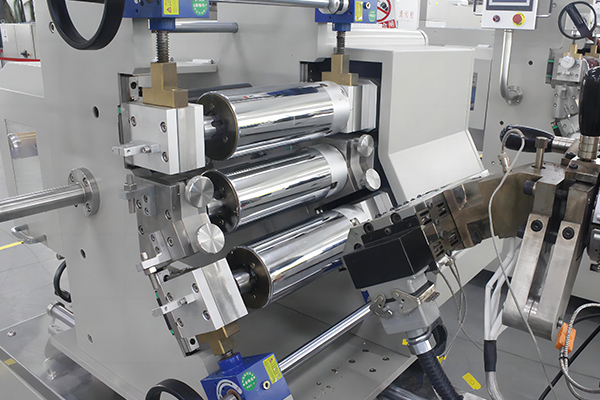

Desktop Small Precision Extrusion Calender

FPBL-35/30

The desktop small precision extrusion calender integrates a precision single screw extruder, a sheet die head, and a precision calender auxiliary machine into one experimental equipment. It can realize all the functions of screw plasticizing extrusion, calendering, traction, trimming, winding, and edge trimming of a calendering production line. It is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for calendering of polymer materials.