-

Film Biaxial Stretching Apparatus

FOHI-10

Send Email Details

The film biaxial stretching instrument consists of a clamping assembly, a stretching assembly, a stretching mechanism moving assembly, a hot oven assembly, a pneumatic air curtain assembly and an electrical control system. It can stretch a square film sample of a certain size at the required stretching ratio and stretching speed at a suitable temperature, and accurately control its performance. The instrument can collect data during the stretching process with high accuracy and good repeatability; the modular design based on ergonomics makes it easier to operate and use, which can greatly improve experimental efficiency and shorten product development cycle. It is an ideal experimental equipment for scientific researchers. -

Small Precision Film Longitudinal Stretching Machine

FOVU-35/02

Send Email Details

The small precision film longitudinal stretching machine consists of an unwinding frame, a preheating roller group, a stretching roller group, an annealing roller group, a cooling roller group, a traction/winding/edge-retracting assembly and an electronic control system. It can perform continuous offline longitudinal stretching of the film material at the required stretching ratio and stretching speed at a suitable temperature, and accurately control its performance. The vertical structure design occupies a small area; the modular design based on ergonomics is more convenient to operate and use, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for scientific researchers. -

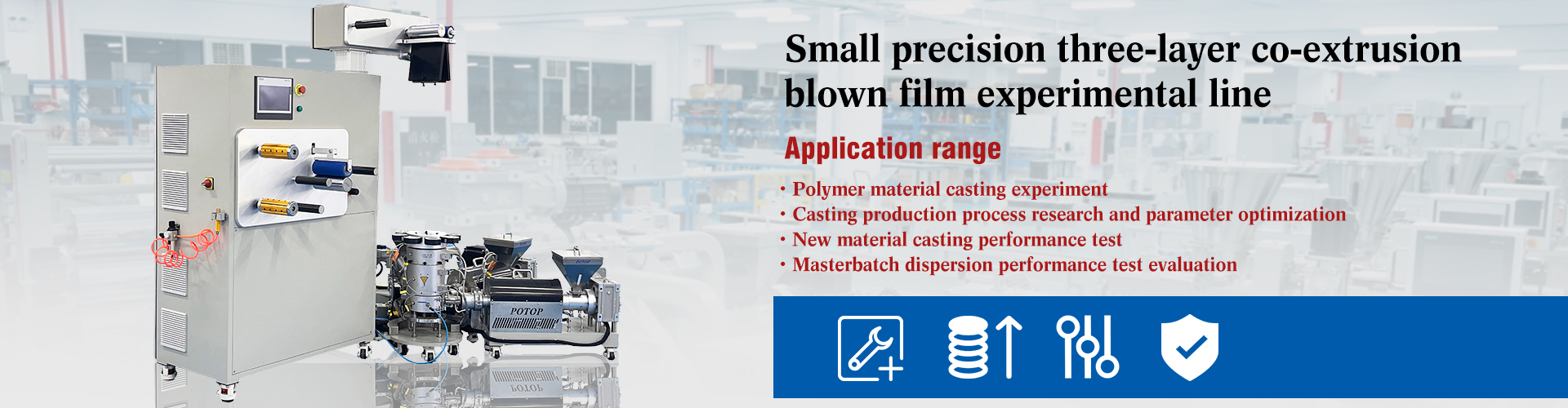

Small Precision Three-Layer Co-Extrusion Blown Film Experimental Line

FBCL-20/03

Send Email Details

The small precision three-layer co-extrusion blown film experimental line consists of three precision single-screw extruders, three-layer co-extrusion blown film die heads and blown film auxiliary machines. The equipment integrates the company's latest precision extrusion and high-performance blown film forming technology, with a wide process adjustment range and wide applicability. It can be widely used in the blown film performance test of polymer materials and the research of multi-layer blown film forming process. The modular design based on ergonomics is more convenient to operate and use, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for scientific researchers. -

Small Precision Extrusion Casting Test Line

FDSI-22

Send Email Details

The small precision extrusion casting experimental line consists of a precision single screw extruder, a set of casting die head, and a set of precision casting auxiliary machine set, which can realize all functions of screw plasticizing extrusion, casting, traction, edge cutting, winding, and edge collection of a casting line; the split structure is easy to carry and move, and the integrated design is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for polymer material casting molding. -

Small Precision ABA Co-Extrusion Casting Experimental Line

FPCL-20/30

Send Email Details

The small precision ABA co-extrusion casting experimental line integrates 2 precision single-screw extruders, 1 set of three-layer co-extrusion casting die head, and 1 set of precision casting auxiliary machine into one experimental equipment, which can realize all functions of multi-layer extrusion, casting, pulling, trimming, winding, and trimming of a casting line. It is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for co-extrusion casting of polymer materials. -

Split Small Precision Twin-Screw Extrusion Granulation Line

MGPL-22/40

Send Email Details

The split small precision twin-screw extrusion granulation line consists of a split small precision twin-screw extruder, a screen changer, a granulation mold, a cooling water tank, an air drying device and a pelletizer. The extrusion mixing system has a split integral barrel and parallel meshing co-directional twin screws, which have better matching accuracy and smaller gaps. Through the combination of threaded elements, high-performance mixing and extrusion of materials with different characteristics can be achieved. It is mainly used for laboratory processing such as filling, blending, and modification of polymer materials. It is an ideal experimental equipment for the research and development of new materials.

- Home

-

Our Services

- Film Biaxial Stretching Apparatus

- Small Precision Film Longitudinal Stretching Machine

- Small Precision Three-Layer Co-Extrusion Blown Film Experimental Line

- Small Precision Extrusion Casting Test Line

- Small Precision ABA Co-Extrusion Casting Experimental Line

- Split Small Precision Twin-Screw Extrusion Granulation Line

- Desktop Small Precision Extrusion Casting Machine

- Desktop Small Precision Extrusion Calender

- Desktop Small Precision Mixer

- Torque Rheometer

- Film Biaxial Stretching Apparatus

- Small Precision Film Longitudinal Stretching Machine

- Small Precision Three-Layer Co-Extrusion Blown Film Experimental Line

- Small Precision Extrusion Casting Test Line

- Small Precision ABA Co-Extrusion Casting Experimental Line

- Split Small Precision Twin-Screw Extrusion Granulation Line

- Desktop Small Precision Extrusion Casting Machine

- Desktop Small Precision Extrusion Calender

- Desktop Small Precision Mixer

- Torque Rheometer

- Display

- Solutions

- News

- About

- Contact Us

- Partners