-

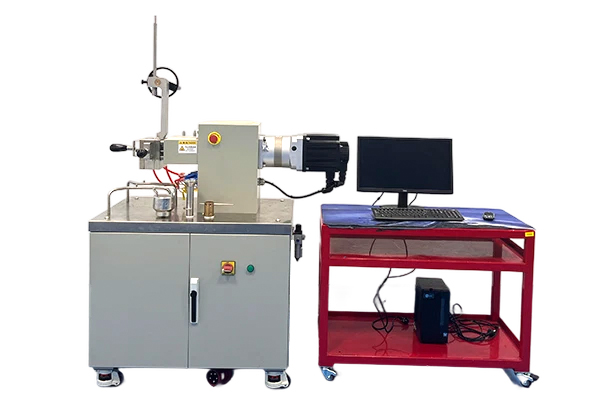

Desktop Small Precision Extrusion Casting Machine

MESI-25/28

Send Email Details

Product Introduction

The desktop small precision extrusion casting machine integrates a precision single screw extruder, a set of casting die head, and a set of precision casting auxiliary machine into one experimental equipment, which can realize all functions of screw plasticizing extrusion, casting, pulling, trimming, winding, and edge collection of a casting line. It is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for polymer material casting molding. -

Desktop Small Precision Extrusion Calender

FPBL-35/30

Send Email Details

The desktop small precision extrusion calender integrates a precision single screw extruder, a sheet die head, and a precision calender auxiliary machine into one experimental equipment. It can realize all the functions of screw plasticizing extrusion, calendering, traction, trimming, winding, and edge trimming of a calendering production line. It is easy to use and operate, which can greatly improve the experimental efficiency and shorten the product development cycle. It is an ideal experimental equipment for calendering of polymer materials. -

Desktop Small Precision Mixer

LKOI-06

Send Email Details

The torque rheometer measures the torque and temperature changes of the material under the kneading effect of a pair of rotors rotating in opposite directions to obtain the "rheological spectrum" of the processing process, and realizes the relative measurement of the rheological properties of the measured material. It can study the dispersion performance, flow behavior and structural changes (cross-linking, thermal stability, etc.) of the material during the processing process, such as the mixing of multi-component materials, cross-linking and curing of thermosetting resins, vulcanization of elastomers, dynamic stability of materials and the influence of screw speed on the processing performance of the material system, etc. It provides experimental guidance for material formulation design, process parameter optimization, and production quality control. It is a general instrument for testing polymer processing performance. -

Torque Rheometer

RTHI-06/02

Send Email Details

The torque rheometer is an ideal device for studying the flow, plasticization, heat and shear stability of materials. The rheometer provides a dynamic measurement method that is closer to actual processing. It can continuously, accurately and reliably measure the rheological properties of materials under conditions similar to actual processing, such as the mixing of multi-component materials, cross-linking and curing of thermosetting resins, vulcanization of elastomers, dynamic stability of materials, and the influence of screw speed on system processing performance.

- Home

-

Our Services

- Film Biaxial Stretching Apparatus

- Small Precision Film Longitudinal Stretching Machine

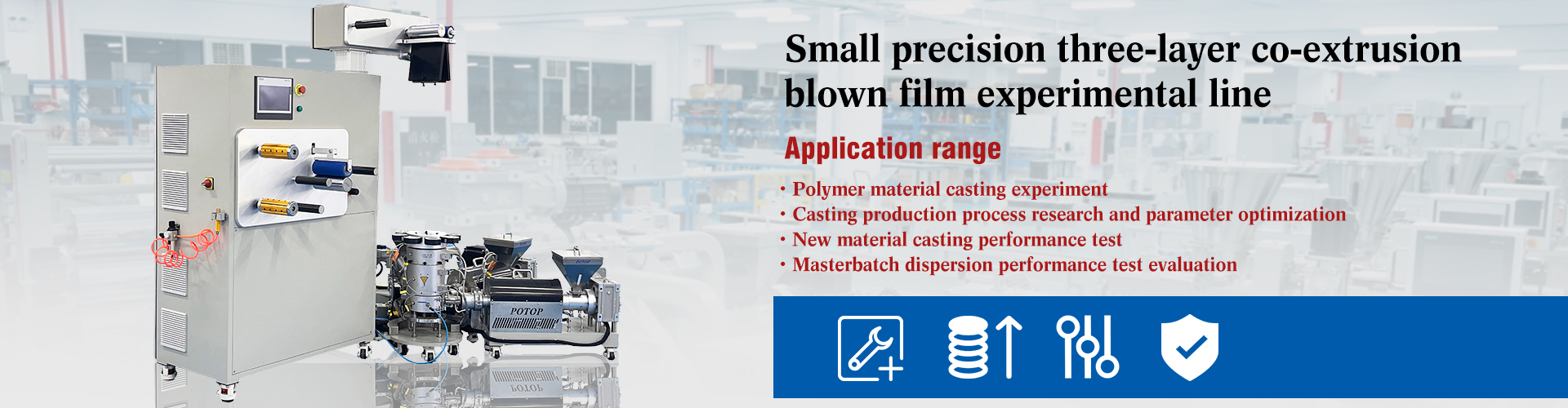

- Small Precision Three-Layer Co-Extrusion Blown Film Experimental Line

- Small Precision Extrusion Casting Test Line

- Small Precision ABA Co-Extrusion Casting Experimental Line

- Split Small Precision Twin-Screw Extrusion Granulation Line

- Desktop Small Precision Extrusion Casting Machine

- Desktop Small Precision Extrusion Calender

- Desktop Small Precision Mixer

- Torque Rheometer

- Film Biaxial Stretching Apparatus

- Small Precision Film Longitudinal Stretching Machine

- Small Precision Three-Layer Co-Extrusion Blown Film Experimental Line

- Small Precision Extrusion Casting Test Line

- Small Precision ABA Co-Extrusion Casting Experimental Line

- Split Small Precision Twin-Screw Extrusion Granulation Line

- Desktop Small Precision Extrusion Casting Machine

- Desktop Small Precision Extrusion Calender

- Desktop Small Precision Mixer

- Torque Rheometer

- Display

- Solutions

- News

- About

- Contact Us

- Partners